Overview:

Since the fiberglass compression molding process has some outstanding advantages, it plays an important role in the FRP molding process. In recent decades, an important direction of the development of molded glass fiber reinforced plastic products in China is the manufacture and application of special types of FRP products with high strength or high temperature resistance and corrosion resistance. In such molded products, the content of glass fibers can be as high as 60% or more, and phenolic or modified phenolic, epoxy resin, epoxy-phenolic type binders are often used. In the preparation and molding process of high-strength glass fiber molding materials, the most widely used and fastest-growing method is the molding process of short-fiber molding materials. The preparation and molding process of short fiber molding materials is the main content discussed in this section.

Main raw materials:

Resin:

1.Phenolic resin:

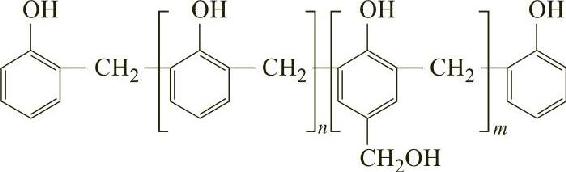

A resin obtained by polycondensing a phenol compound and an aldehyde compound is called a phenol resin, and a phenol resin obtained by polycondensing phenol and formaldehyde is most important. As one of the three major thermosetting resins, phenolic resin is widely used and has a large output. The structural formula of the phenolic resin can be expressed as:

n = 2 to 10 and m = 2 to 5.

1).Performance characteristics of phenolic resin The phenolic resin has the following main features: low raw material price, simple and mature production process, low investment in manufacturing and processing equipment, easy molding and processing; resin can be mixed with inorganic filler or organic filler to make molding compound, or The impregnated fabric is made into a laminate, which can also be foamed; the product has stable dimensions; heat resistance, flame resistance, self-extinguishing, good electrical insulation, good chemical stability, strong acid resistance, but poor arc resistance and alkali resistance.

2).Basic properties of phenolic resin Compared with other thermosetting resins, phenolic resin has higher curing temperature. The mechanical properties and chemical corrosion resistance of the resin after curing can be comparable to that of unsaturated polyester resin, but less than epoxy resin; brittleness of phenolic resin Larger, higher shrinkage than polyester resins and epoxy resins.

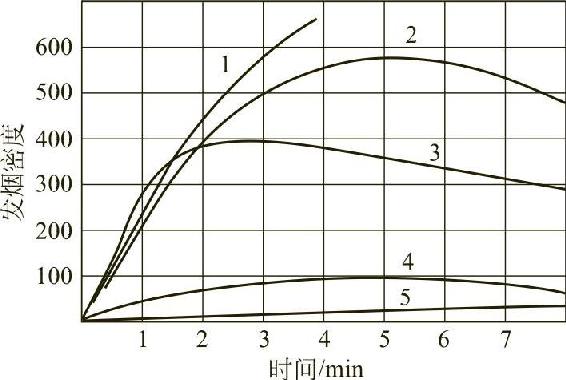

3).Smoke-generating properties of phenolic resin The smoking characteristics can be determined by a combined optical system in a smoke density box according to standards, and the toxicity of smoking can also be determined. The smoke density of thermoset composites is shown in Figure 4-1.

Figure 4-1 Smoke density of thermoset composites (NBS smoke density box)

1—Polyurethane laminate; 2—Epoxy resin sandwich panel; 3—Epoxy resin laminate; 4-Phenolic resin sandwich panel; 5-Phenolic resin laminate

Phenolic resin composites are non-flammable, low smoke generation, and emit little or no toxic gases. Their properties in fire such as flammability, heat release, fuming, toxicity and flame retardancy are far superior to epoxy resins. Unsaturated polyester resin, vinyl ester resin.

4). Modified phenolic resin The structure of the phenolic resin is a methyl group sandwiched between two phenols. This structure causes the density of the rigid group (benzene ring) to be too large, the steric hindrance is large, and the degree of freedom of rotation of the link is small, resulting in pure phenolic The resin has poor impact resistance, that is, poor toughness. At the same time, heat resistance is also affected because the phenolic hydroxyl group and the methylene group are easily oxidized. However, with the rapid development of the industrial economy, higher and higher requirements have been placed on the performance of phenolic resins. For example, with the development of various vehicle, aerospace and other advanced defense technologies, high performance phenolic resin-based friction materials have been developed. Thermal insulation and ablation resistant materials have placed higher demands, and some industrial sectors have imposed more stringent requirements for high temperature resistance, high strength and strong adhesion to phenolic resin coatings and adhesives. Therefore, modification of phenolic resin to improve its toughness and heat resistance has become the core content of phenolic resin research. In fact, pure phenolic resins are rarely used in the manufacture of FRP, and most of them use modified phenolic resins.

A-Aminophenol phenolic resin. Aminophenol phenolic resin is a phenolic resin prepared by polycondensation and dehydration using ammonia as a catalyst. The product made of aminophenol phenolic resin has good ablation resistance and erosion resistance. The carbon layer formed by carbonization of the aminophenol phenolic resin is hard and has a tendency to be graphitized, and the phenolic phenolic resin can only form amorphous carbon even if it is carbonized at 2000 °C. Therefore,the ammonia phenolic resin has better ablation resistance than the phenolic phenolic resin. The disadvantage is that the product belongs to slow molding, the fluidity during molding is not good, and it is not easy to fill the cavity, and it is difficult to ensure the uniformity of the product.

B–Magnesium phenolic resin. Magnesium phenolic resin is a thermosetting resin modified by aniline and polyvinyl butyral under the action of magnesium oxide as a catalyst. It is characterized by good fluidity and is suitable for compression molding. The product has high mechanical strength, good electrical insulation and heat resistance.

C–Polyamide modified phenolic resin. The polyamide modified phenolic resin (nylon phenolic) is a modified phenolic resin using a methylol polyamide as a raw material. The polyamide-modified phenolic resin not only maintains the advantages of the phenolic resin, but also improves the impact toughness and adhesion of the phenolic resin and improves the fluidity of the resin. The glass fiber reinforced plastic made of the resin has high mechanical properties, high impact strength and good molding process. The resin can be used for preparing products with high mechanical properties, heat resistance and wear resistance, and is suitable for making rapid-form glass fiber reinforced plastic.

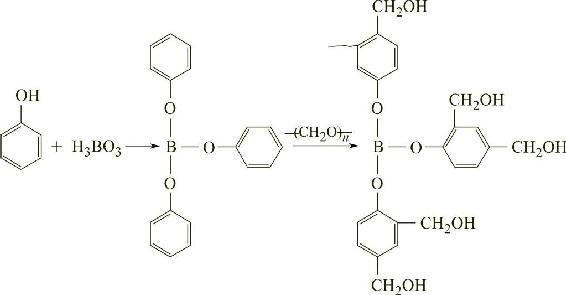

D–Boron phenolic resin. The boronic acid phenolic resin is formed by reacting boric acid with phenol to form a phenolic phenolic acid ester, which is then reacted with a paraformaldehyde or aqueous formaldehyde solution to form a boron-containing phenolic resin. The synthesis methods of boron phenolic resin are mainly divided into two categories. One type is the reaction of boric acid and phenol to form phenyl borate, and then reacted with paraformaldehyde or aqueous formaldehyde to form a boron-containing phenolic resin. Its reaction formula is as follows:

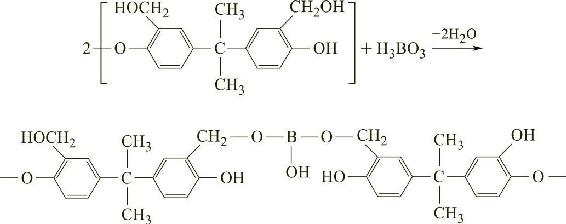

The other is to first react phenols with aqueous formaldehyde to form salicyl alcohol, and then react with boric acid. The esterification reaction in the synthesis process is as follows:

Since boron is introduced into the molecular structure of the boron phenolic resin, the bond energy of the boron-oxygen bond is high, resulting in high temperature thermo-oxidation stability better than that of the general aminophenol resin and the phenolic resin. The cured product has a decomposition temperature of up to 625 ° C in an inert atmosphere and a residual carbon value of 70% at 900 ° C.

The boron phenolic resin can impart excellent thermal properties, high mechanical strength and good electrical properties to the molded article, but has poor moisture resistance and alkali resistance, and is difficult to demold at the time of press molding.

E–New phenolic resin. The novel phenol resin (polyphenol ether resin) is a condensate of an aryl alkyl ether and a phenol, that is, a polyaralkyl phenol resin, and is a novel thermosetting resin having high thermal stability. The synthesis method is to use an aralkyl halide or an ether thereof (such as dichloromethylbenzene, phthaldimethyl dimethyl ether) and a phenol or other aromatic compound in a Friedel-Crafts catalyst ( The most commonly used is polycondensation to obtain a polyaralkyl phenol resin in the presence of tin tetrachloride.

The resin has good ablation resistance, and has excellent chemical resistance, dielectric properties, mechanical properties, and good radiation resistance and adhesion. The resin has fast curing characteristics and good moldability, and the molded article has excellent electrical properties, mechanical strength, chemical resistance and heat resistance. It can be used as ablation resistant material on spacecraft and missile nozzles.

F–Silicone modified phenolic resin. The silicone modified phenolic resin has excellent properties such as high heat resistance, low heat loss, and good toughness. The preparation method mainly comprises the following steps: (1) reacting a phenolic resin with an alkoxy-containing organosilicon compound to form a three-dimensional network containing a silicon-oxygen bond structure; (2) reacting an allyl phenolic resin with an organosilicon compound to form an excellent heat resistance. Silicone modified phenolic resin. In view of the shortcomings of low molecular weight volatiles during the curing of phenolic resins, some addition polymerization type phenolic resins have been developed at home and abroad.

2.Expoxy Resin:

Epoxy resin refers to two or more epoxy groups. It is based on organic compounds such as aliphatic, alicyclic or aromatic, and can be formed by the reaction of epoxy groups. A polymeric oligomer of a thermoset product. The epoxy resin contains a unique epoxy group, and a reactive group such as a hydroxyl group or an ether bond, and a polar group, and thus has many excellent properties. Compared with other thermosetting resins, epoxy resins have the most types and grades and different properties. A wide range of epoxy resin curing agents, plus a large number of accelerators, modifiers, additives, etc., can be combined and assembled in a variety of ways, so that a variety of excellent performance, each with its own characteristics The epoxy curing system and cured product can meet and meet various performance and process performance requirements. The basic properties of the epoxy resin and its cured product are as follows.

1). High mechanical properties. Epoxy resin has strong cohesive force and dense molecular structure, so its mechanical properties are higher than general-purpose thermosetting resins such as phenolic resin and unsaturated polyester resin.

2).Curing shrinkage rate is small. Generally, it is 1% to 2%, which is one of the varieties with the lowest curing shrinkage rate in thermosetting resin (8% to 10% for phenolic resin; 4% to 6% for unsaturated polyester resin; 4% to 8% for silicone resin) %). The coefficient of linear expansion is also small, generally 6 × 10 -5 ° C -1 . Therefore, its product size is stable, the internal stress is small, and it is not easy to crack.

3).Good craftsmanship. When the epoxy resin is cured, substantially no low molecular volatiles are produced, so that it can be formed by low pressure molding or contact compression molding. The flexibility of the formulation design allows for the formulation of formulations that are suitable for a wide range of process requirements.

4).Electrical performance is good. It is one of the best electrical properties of thermosetting resins.

5).Stability is good. Epoxy resins that do not contain impurities such as alkali and salt are not easily deteriorated. As long as they are stored properly (sealed, not exposed to moisture, and not exposed to high temperatures), the storage period is one year. If the test is passed after the expiration date, it can be used. Epoxy cured products have excellent chemical stability, and their resistance to corrosion by various media such as alkali, acid and salt is better than that of unsaturated polyester resins and phenolic resins.

6)The heat resistance of the 6 epoxy cured product is generally 80 to 100 °C. Epoxy resin heat resistant products can reach 200 ° C or higher.

Reinforcement materials:

In the short fiber molding process, the reinforcing materials used are mostly fiber-type reinforcing materials. Fiber-reinforced materials are mainly glass fibers and high-silicon fibers, and carbon fibers, nylon fibers and asbestos fibers are sometimes used. The length of the molded glass fiber is generally 15 to 50 mm, especially 30 to 50 mm, and the content thereof is generally in the range of 30% to 50%.

Glass fiber types include open wire, roving, twisted yarn and high strength fibers. The open wire is a waste product in the production of glass fiber, with a medium alkali or an alkali-free open wire. In the molding material, the wire is the most used and the lowest cost, and is used for the less demanding products. The high silica fiber has good corrosion resistance, and it refers to a high purity glass fiber containing 96% of silica produced by the asphalt method. It has good cutting property, strong resin absorbing ability and high strength of molded products, so it is widely used.

In the press molding, in order to increase the rigidity of the product, carbon fiber is sometimes used as the reinforcing material. In FRP products, the combination of carbon fiber and glass fiber can make up for the lack of rigidity. The use of asbestos fiber can improve the heat resistance, acid resistance and corrosion resistance of the molded article, and improve the molding processability of the molded material and the appearance quality of the product.

Origin of the Article:Forming Technology and Application of Composite Materials Editor:Professor:Jiakang Huang

The weld line is due to the fact that the forepart of the melt resin(raw material for plastic inj……

1.Low amount or active ingredient of curing agent and accelerator in hand lay up process. The amou……

The heat treatment of the moulds has a great influence on its service life. Most of the Plasti……