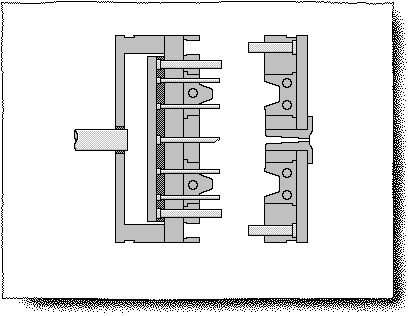

Plastic Injected Part

With years’ experience in custom plastic injection molding, Shanghai Olimy is now supplying both mold and plastic parts for international world class enterprises, including Renault, Siemens, Home depot, Whirlpool etc. Working with

OEM worldwide for a wide range of industries like automotive, construction, medical, machinery and household appliance, enables us to design and mold custom plastic parts with innovation to reduce overall part and production costs for all OEM projects. Our mission is to provide you with competitive advantages in terms of improved quality, efficiencies and increased profitability.

With 29 sets Injection Machines normally we can produce 30000 pcs plastic part each day.The biggest Machine with pressure 1600 Ton can inject maximum 8.00 kgs part.

We have no quantity limition.With small quantity we will study which process is economic,producing injection molding,CNC machining or 3D printing.

| Pressure | Quantity | Model | Auxiliary Equipment | Die Capacity | Die Width | Max Injection Volume |

| 50T | 1 | 140*360 | 360*360 | 28g | ||

| 90T | 2 | 140*360 | 360*360 | 117g | ||

| 130T | 6 | Manipulator | 150*410 | 410*410 | 200g | |

| 170T | 10 | Manipulator | 160*500 | 460*460 | 370g | |

| SM250V | 1 | 195*600 | 560*510 | 600g | ||

| 380H | 2 | 250*720 | 710*710 | 1120g | ||

| 480 | 3 | 300*800 | 800*800 | 1600g | ||

| 650T | 1 | |||||

| 1000T | 1 | Two trigger | Triaxial servo manipulator | 530*1200 | 1300*1200 | 4275g |

| 1300T | 1 | Two trigger | Triaxial servo manipulator | 700*1350 | 1420*1420 | 4275g |

| 1600T | 1 | Two trigger | Triaxial servo manipulator | 700*1500 | 1520*1520 | 8000g |

For custom plastic injection parts, engineering and mold design are the two most important factors for success. Shanghai Olimy is always ready here to provide you with following suggestions and supports:

|

1. |

Stack molds(multi cavities) | |

|

2. |

Molded-in color |  |

|

3. |

In-mold decorating and In-mold labeling | |

|

4. |

Insert molding | |

|

5. |

Over molding | |

|

6. |

Multi-shot molding | |

|

7. |

Silk screening | |

|

8. |

Hot stamping / Pad printing | |

|

9. |

Ultrasonic welding | |

|

10. |

Post molding operations. | |

|

11. |

Assembling |

Engineers and designers in Shanghai Olimy are not only responsible for part design, tool design, mold building, we will be also responsible for material selection. Now Shanghai Olimy is working with well-known brands like Basf, Bayer, LG,DOW , Sabic, etc and you can point some brands directly. Also we will suggest cost effective material according to the application, use objectives, use environment and intended market of your parts.

One Stop Service:

1)logistic service:good relation with several logistic companies,we can supply you door to door service,not only for International Courrier,but also for Air and Sea shipment.

2)we would like to help you to mix other goods from other china suppliers into one shipment,that way can save you costs.