Plastic Injection Molding

More than 7 years’ experience in mold designing and production, now we are supplying both molds and production for Siemens, Renault, Home depot, Whirlpool etc.

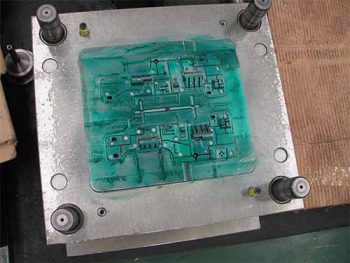

● Once your requirements for mold life, material and mold surface etc are provided, we will study and suggest cavity numbers, steel material, mold base and feeding mode accordingly to save your cost.

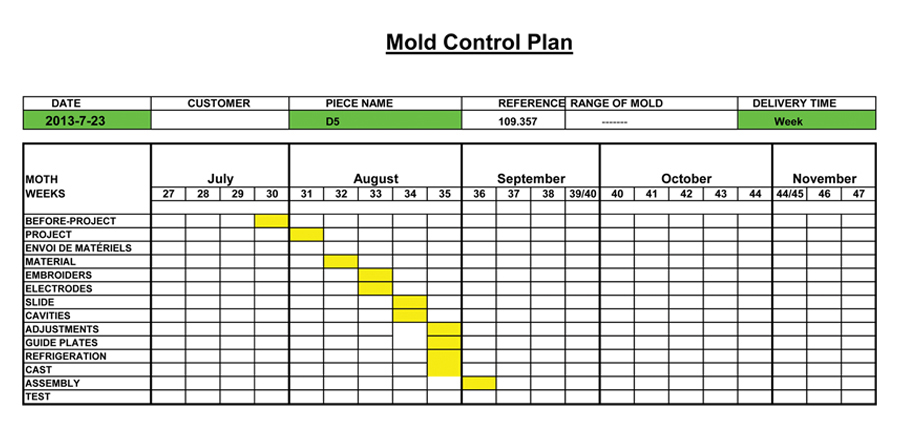

● Mold Control Plan will be provided once order is confirmed, so you can see all detailed processes and how long each process will need.

*Weekly report will be emailed every Tuesday together with pictures, so you are aware of all progressing here just like you yourself are in the workshop.

*Every detail will be processed as signed agreements, if any possible changing or suggestion for improvements during production, we will not start until getting your final confirmation

*Owning 29 sets of injection machine with press from 50 to 1600 ton, enables us to have the ability to test both small molds and big molds in our own workshop, which ensures better quality control and will save some outer-lab mold testing cost for you.

*Once mold is finished, we will test in our own machine and do some adjustments, sample will be provided for free together with Size control report and testing video.

*It’s our duty to do some improvements according to your feedback after checking the sample.

| 1.Machine List | ||

| Machine | Qty | Capacity |

| CNC-EDM | 2 sets | Route:300*300MM |

| CNC Machine | 1 set | Route:1000*650MM |

| Precision Carving&Milling Machine | 1 set | |

| Milling Machine | 5 sets | |

| Other Auxiliary Equipments | 10 sets | |

| 2.Software | ||

| 3D Designing Software | ProE | |

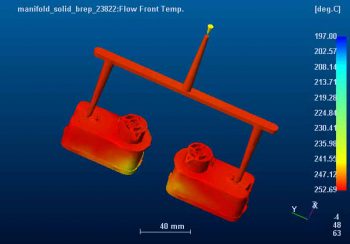

| Solidifaction Simulating Software | MoldFlow | |

| CNC Software | UG | |