3D Printing Technology is not unfamiliar to us. It is one of the most advanced manufacturing methods at present. With the rapid development of 3D printing technology in recent years, 3D printing products begin to transfer rapidly from laboratory to practical application.

At present, 3D printing products have emerged in aerospace, biomedical, mechanical and other fields, and have inadvertently entered people’s clothing, food, shelter, leisure and entertainment activities, constantly adding beautiful scenery to our daily life, creating fresh surprises and joys.

3D printing, also known as add-on manufacturing, mainly refers to the technology of printing objects layer by layer using bindable materials on the basis of digital model files. In today’s medical field, we can successfully perform simultaneous knee arthroplasty for a college student with hemophiliac osteoarthritis by using 3D printing osteotomy navigation template assistant technology.

In addition, with the rapid development of 3D printing applications, innovative technological achievements such as medical scheme formulation of 3D printing simulation experiment, personalized 3D printing capsules, 3D printing human implants and so on have added strong vitality to the development and progress of the world medical level.

3D printing technology has shown great application value and development potential in the field of aerospace. It not only shortens the production cycle of aerospace products, but also reduces the cost, and further improves the product performance. As a new way of production, the products made by space 3D printing can be competent for some tasks that are difficult to accomplish by traditional manufacturing technology.For example, one side of a component needs to withstand high temperature, the other side needs to have high strength and other “stringent requirements”, 3D printing can be a great show.

In addition to printing various components, you can also print delicious food. Three-dimensional printing technology can be used to make the mold for baking dessert. It is based on the digital model file, using bondable materials such as powdered metal or plastic to construct the die by printing layer by layer. With the mold, baking dessert can realize mass customized production.

The technology makes all kinds of food raw materials broken, mixed or concentrated into slurry, which is made into foam and then remolded. This will make the appearance of a variety of food can be “intake is changed”, not only can facilitate the difficult people to swallow better to eat, but also let people enjoy the meal at the same time, can better absorb nutrition.

3D printing is moving towards the technology of material shape and structure changing with time, active regulation of intelligent materials and structures. In the future, it is possible to develop the technology of adding materials for high performance alloy construction, 3D printing of composite materials and composite structures, active regulation of intelligent materials, biological 3D printing with growth and biological activity. Material, from numerical value to metal materials, to ceramic materials, to biological active materials; in industry, from attaching importance to equipment to the application of various fields and the subversive changes brought by cutting-edge science and technology.

Although the prospects are bright, the road is bumpy. At present, 3D printing still faces many technical problems. In the medical field, from hard bones to soft and complex human viscera, people hope that 3D printing can bring more therapeutic breakthroughs. However, the existing 3D printing heart is expensive and can only beat for half an hour. The 3D printing of ligaments, tendons and cartilage tissues is still at the similar stage, and its function is not yet realized.

In order to make 3D printing really go into space, we must solve a series of technical problems, the biggest obstacle is “weightlessness”. In the space environment, materials and glue will “fly up”, which requires special design on the printer structure.In addition, how to solve the problem of exhaust gas diffusion caused by space printing remains to be further studied and improved.

Condition Description Reasons Solution Condition Internal Cracking Due to excessive shr……

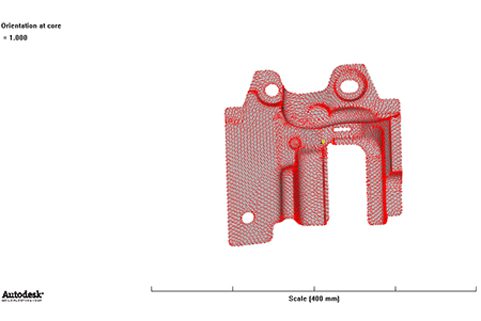

Autodesk Moldflow injection molding simulation software has a simulation tool that can help you va……

/wp-content/uploads/2019/07/Mould-Flow-Analysis-Report-for-Plastic-Injection-Molding-1.mp4 Autode……