| Condition | Description | Reasons | Solution |

| 1 | a semicircular swell on the surface of solidified fiberglass compression molding part. | Entrapped air between fiberglass sheets. | Remove the interlayer air by pre-pressing method and reduce the feeding area to facilitate the discharge of air. |

| 2 | The tooling temperature is too high (evaporation of monomer). | low tooling temperature. | |

| 3 | Solidifying period is too short (evaporation of monomer). | Extend solidifying period. | |

| 4 | dry fiber | Reduce the viscosity of the resin.Install more work rolls in the impregnation area, and heat the dip rollers.Replace the glass fiber. | |

| 5 | There are burrs in the cavity of fiberglass compression tooling. | Carefully remove the burrs in cavity of tooling. | |

| 6 | Fiberglass sheet is too soft. | Increase the thickening of fiberglass SMC raw material or increase the content of thickener. |

/wp-content/uploads/2019/07/Mould-Flow-Analysis-Report-for-Plastic-Injection-Molding-1.mp4 Autode……

With the development of the plastics injection molding industry, people have higher and higher req……

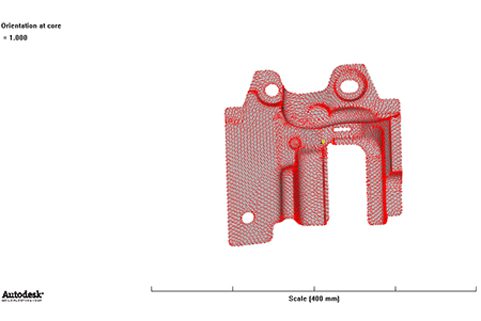

Autodesk Moldflow injection molding simulation software has a simulation tool that can help you va……