5 Aug, 2022 By Johny 2 Comments

Surface modification makes Carbon Fiber composites tougher

In real life, the performance of composite materials may depend on the interfacial compatibility between different components. One of the most challenging composite material combinations is Carbon Fiber and Polypropylene.

Luke C. Henderson of Deakin University, Australia, points out: “Polypropylene polymers have extremely poor compatibility with Carbon Fibers. We wanted to see if surface modifications could be used to enhance this compatibility and ultimately improve the physical properties of this composite material for wider use.”

Polypropylene is one of the most widely used thermoplastics because it is easy to process, inexpensive to produce, and very durable. Its mechanical properties can be enhanced by reinforcing materials such as Glass Fibers or Carbon Fibers. However, Polypropylene’s inert molecular structure makes it difficult to bond with embedded Carbon Fibers, so additional ingredients (i.e. comonomers) are often added to improve compatibility. However, this means greater processing difficulty, higher production costs and other costs.

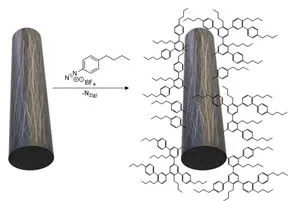

Henderson and colleagues at the DEVCOM Army Research Laboratory used the electrical conductivity of Carbon Fibers to modify their surfaces with small molecules using an electrochemical modification method. Electrochemical grafting of n-butylphenyl groups to the fiber surface and incorporation into Polypropylene increased the toughness of the composites by 30-32%. Compared to untreated fibers, composites with surface-modified fibers can withstand greater impact before failure without adversely affecting other physical properties.

Doing so, Henderson explained, makes the surface of the fiber more like that of Polypropylene, while trying to capture 100 percent of the potential interactions with the bulk polymer.

Since the method uses covalent bonds to attach small molecules to the fiber surface, they cannot be removed like a coating, so it is stronger. The process is also quick, irreversible, and much gentler than many of the treatments used in carbon fiber processing.

Similar electrochemical methods have been used in Carbon Fiber production for nearly 50 years, so Henderson’s team’s modification strategy can be directly mapped onto existing large-scale infrastructure.

The team has also produced modified fiber composites at a pilot-scale facility and is now working to improve other physical properties, such as tensile strength and stiffness. The improved composites could dramatically improve the performance of hydrogen pressure vessels or automotive components that are prone to minor impacts, where impact resistance is often critical.

Sourcing from:www.cnfrp.com