Ultraviolet light is the main reason to the application of anti sunshine. FRP made of vinyl ester resin, unsaturated polyester resin or epoxy resin will degrade the surface resin after long-term exposure to ultraviolet light, resulting in yellowing and powdering of the surface, which will reduce the strength. Usually the following measures can be taken:

1.Polyester resin products can be protected by coating with anti-ultraviolet and anti-corrosion coatings, such as acrylic coatings.

2.During the production stage, UV absorbers (such as 0.3% UV-9) can be added to the outer layer resin. The UV absorbers may affect the curing time of the resin, so tests should be carried out before mass addition. It is noteworthy that ultraviolet absorbent can only delay the occurrence of yellowing and pulverization.,therefore, in the design of anti-corrosive scheme, it is necessary to avoid the long-term exposure.

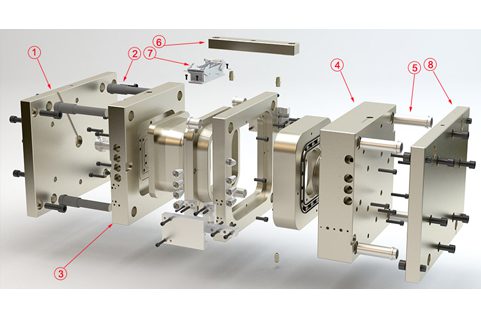

Item Description Function 1 Top clamp plate To connect the compression mold with the hydraul……

Condition Description Reasons Solution Condition 1: Not fully filled at the edge of the……