Fiberglass RTM

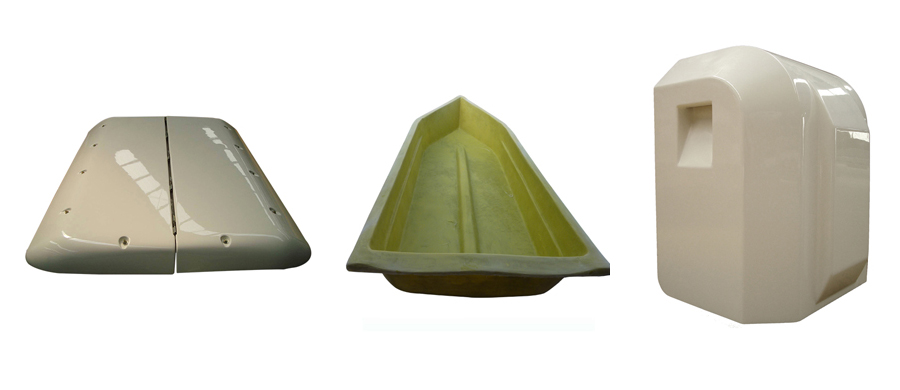

RTM is resin transfer molding. Two smooth surfaces is the major advantage of this process. Comparing to hand lay up, artificial factor is not so important. The production cycle time is also much shorter. Through this process, we have made parts for auto components, basins and toilets.

FRP Resin Transfer Molding(RTM) has the following main features:

(1) FRP RTM technology consists of two steps: processing reinforced material preform and curing resin injection. Two steps can be performed separately, with high flexibility and modularity, can realize the “material design”.

(2) FRP RTM technology is mold closing forming ,through enhancing the infiltration of raw material and resin to make the resin to flow fast in sealed cavity, not like the manual infiltration of hand lay-up process and injection process, or prepreg technology, or the mechanized infiltration of SMC whose cost is very expensive.RTM is a low cost, high quality semi-mechanized fiber / resin infiltration process.

(3) FRP RTM technology adopts performing technology of the reinforced material Preforming Technology with similar shapes, fiber / resin infiltration can be cured by complete, so it can be used for low viscosity fast curing resin, and can be used for heating and further improve the production efficiency and product quality.

(4) reinforced preform material body can be chopped strand mat, continuous fiber, fiber cloth, no fold fabric, knitted fabric and three-dimensional 3D braided fabrics, and can choose according to the performance requirements, to enhance local contrast enhancement, hybrid and the use of embedded and sandwich structure, can make full use of design the properties of the composite materials.

(5) FRP RTM process of closed die resin injection method can greatly reduce the toxic harmful components of resin to human body and environment, meet the advanced industrial countries to styrene volatilization of harmful gas concentration is more and more strict restriction.

(6) FRP RTM by low-pressure injection technique ( – injection pressure <0.4MPa), is conducive to the overall structure of preparing large size, complex shape, smooth on both sides.

(7) the mold can select different materials according to the scale of production requirements, in order to minimize the costs.

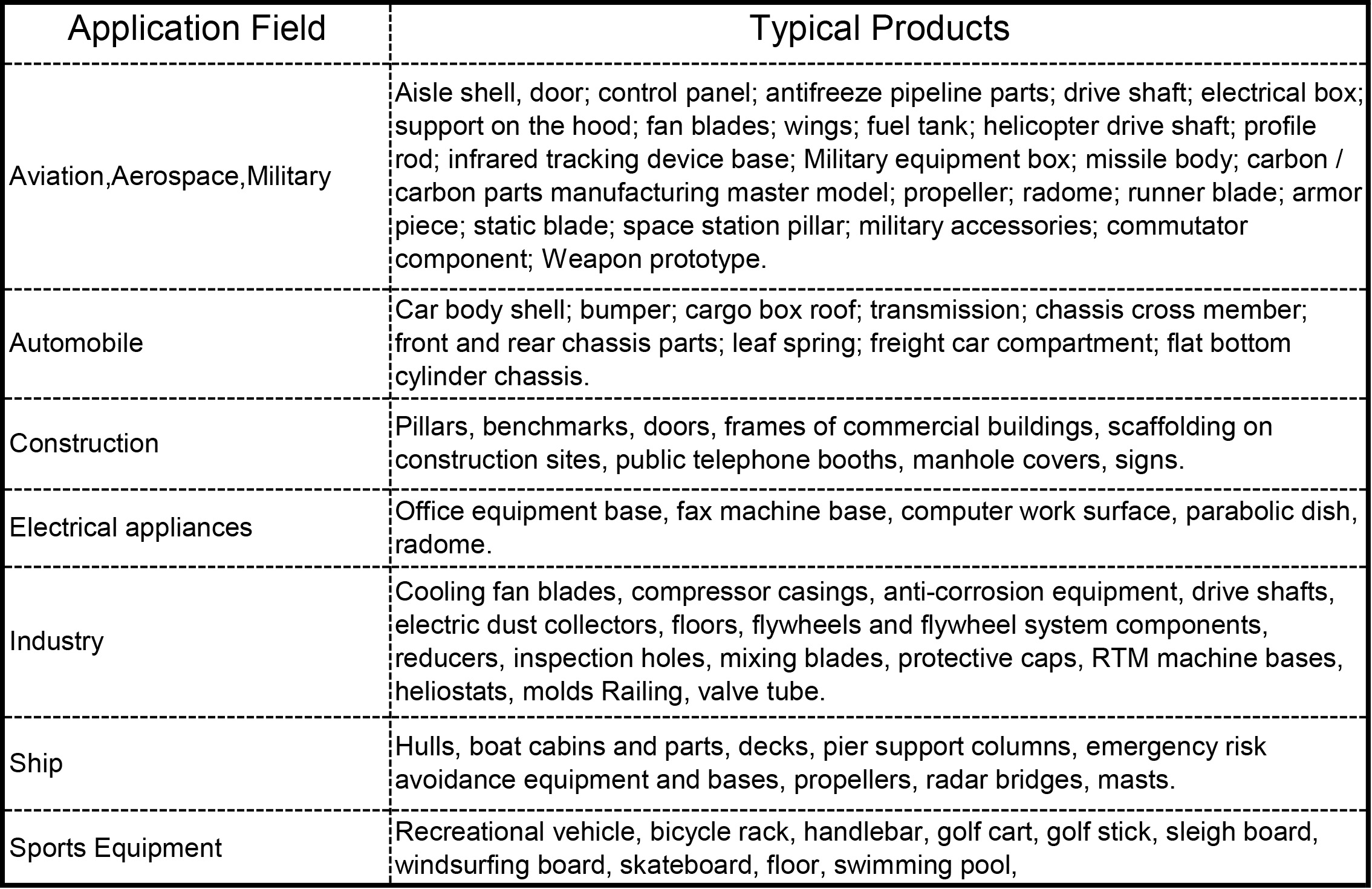

Typical applications of Fiberglass RTM products:

With the continuous development of material technology and process technology,Fiberglass RTM(Resin Transfer Molding) process products have been widely used in Aerospace,Transportation,Sports Goods,Ships,construction and other fields. Due to the characteristics of the RTM process, its process advantages are more prominent in the manufacture of large parts and parts with high structural performance requirements.