Polyester Molding Fiberglass (hereinafter referred to as SMC / BMC) are mainly composed of unsaturated polyester resin, filler and reinforcement material, as well as chemical thickener, internal release agent, curing agent, low shrinkage additive, colorant and other additives. In the SMC / BMC formulation, adding different kinds and quantities of additives is of great significance to the improvement of some special properties of the material. Therefore, the following is a brief description of various materials used in SMC / BMC.

1.Reinforcing material:

Glass fiber is one of the basic components of SMC. Its various characteristics have obvious influence on SMC production process, forming process and product performance. The general requirements for SMC special fiber are good cutting performance, good wettability, good fluidity, high product strength and good appearance quality. The types of glass fiber used in SMC are chopped strand mat and roving.

Chopped strand mat is a kind of mat made of chopped strand and arranged uniformly and disorderly. The length of glass fiber is 25 mm and 50 mm. Sometimes, it is mixed. The thickness of chopped strand mat is generally 1.0-2.3m m, and the unit weight is 230-900g / M 2. According to the combination mode of chopped strand felt, it can be divided into emulsion adhesive felt, powder adhesive felt and mechanical adhesive felt. The latter two are commonly used in SMC. In order to avoid scour, low solubility binders are usually used, which are insoluble in styrene. The SMC sheet made of chopped strand mat has a uniform single weight.

Chopped strand mat is a kind of mat made of chopped strand and arranged uniformly and disorderly. The length of glass fiber is 25 mm and 50 mm. Sometimes, it is mixed. The thickness of chopped strand mat is generally 1.0-2.3m m, and the unit weight is 230-900g / M 2. According to the combination mode of chopped strand felt, it can be divided into emulsion adhesive felt, powder adhesive felt and mechanical adhesive felt. The latter two are commonly used in SMC. In order to avoid scour, low solubility binders are usually used, which are insoluble in styrene. The SMC sheet made of chopped strand mat has a uniform single weight.

In SMC, the cutting length of roving can be 6mm, 12mm, 25mm, 50mm, but generally 25mm. Increasing the fiber length can improve the molding efficiency and product strength, but when the fiber length is increased to a certain extent, there will be no greater benefit. The fiber content of SMC is generally 20% – 40%. The content of glass fiber depends on the strength requirements of products. But if the content of glass fiber is too high or too low, it will increase the difficulty of production technology. If the content of glass fiber is too high, it will also cause the forming difficulty.

Twistless roving is a cylindric yarn which is made of many strands of raw silk in parallel. It is the main reinforcement material used by SMC. The key characteristics of twistless roving for SMC include count, banding, dispersion of yarn bundles, geometry of yarn bundles and sizing agent. In the SMC process, the properties related to fibers are infiltration, permeability and resilience. The following describes the wettability, permeability and resilience of roving for SMC.

(1)Wettability:

In SMC process, the wettability is defined as the extent to which the yarn bundle is coated with resin paste. If there is white yarn in SMC sheet, it indicates poor wettability. The wettability of SMC sheets was measured immediately after they were made into sheets. Take out a certain length of sheet from SMC sheet, uncover the PE film on it, cut the sheet in the direction perpendicular to the forward direction of the machine, and expose the section of sheet. If the operation is reasonable, the cross section of the sheet can be seen, and the quantity and size of white yarn on the cross section can be measured and compared with the standard provisions. The measurement of the wetting characteristics is of great significance for the selection of glass fibers. The existence of white yarn will cause bubbles or air holes on the products. The tiny white yarn can not be treated, and the defect can be eliminated by thickening process.

(2)Permeability:

Permeability is a sign of the integrity of SMC sheet. It is a semi quantitative method to evaluate the resin penetration degree of SMC sheet in the direction of reinforcement material after compaction, which is a subjective measurement method. At the winding position of SMC unit, the permeability was evaluated by observing the fiber protrusion on the surface of sheet with PE film.

Permeability is also a sign of styrene insolubility and yarn integrity. The degree of penetration can be used to characterize the fluidity of the yarn during molding. The soakage agent has high solubility and low permeability. During the cutting process, the soft and flexible fibers are easy to be divided into monofilament, which leads to the decrease of the permeability of the sheet.

(3)Rebound Resilience:

SMC sheet is formed, there is a tendency of upward uplift in the sheet without tension, which is called resilience. The rigid glass fiber does not soften in the process of infiltration and compaction, and it will rise after forming into pieces. Under the pressure, the shape and curvature of the fibers will change. After the pressure is removed, they will return to the natural state; the viscosity or adhesion of the resin paste is not enough to stick the fibers together. After the pressure is relieved, the sheets will rebound. The springback degree will affect the quality of SMC products. High degree of rebound, the possibility of air into the molded products is great, will increase the porosity of the molded products.2.Resin:

As the main matrix of unsaturated polyester resin, its main role is to bond the reinforcement material and filler together, and play a role in protecting the reinforcement material, so that the reinforcement material can be uniformly stressed under external load at the same time. In addition, SMC molding plastics can also be endowed with good formability, rapid curing process, good product appearance, high thermal deformation temperature, long-term storage stability and high product size accuracy. In the case of special requirements, it can also be endowed with electrical insulation and flame retardant properties. Therefore, the following requirements are put forward for unsaturated polyester resin used in SMC molding plastics.

(1) it is necessary to have good wettability for reinforcing materials and fillers, so as to improve the bonding strength between resin and glass fiber.

(2) the resin shall have proper viscosity, generally the initial viscosity shall be low, so as to meet the requirements of high filling amount of filler, but also have good fluidity, so as to meet the requirements of molding process, so that in the molding process, both resin and glass fiber can flow at the same time and fill all corners of the mold cavity to obtain the molding products with uniform strength.

(3) the curing temperature of the resin should be low, the volatile matter in the curing process should be less, and the processability should be good (such as easy adjustment of viscosity, good mutual solubility with various solvents, easy demoulding, etc.), and it can meet the specific performance requirements of molded products, etc. In addition, from the application or other point of view, the resin should also meet some other special performance requirements, such as corrosion resistance, heat resistance, etc.

(4) from the perspective of production efficiency, resin is required to have a faster curing speed, but for some large-scale products with complex structure and high requirements, the curing speed can be properly controlled.

(5) in addition, the resin can also have a storage period of several weeks to several months with the addition of initiator, but it can cure rapidly under the condition of molding temperature rise. The curing parameters of the resin must meet the requirements of molding process. The gel and curing time should be short, and the curing and demoulding of the products can be finished within 1.5 ~ 3min.

(6) strictly control the water content in the resin. The water content of polyester resin has a great relationship with the viscosity rise in the process of resin thickening, and will eventually affect the average viscosity of the resin. The water content must be accurately controlled between 0.1% and 0.15%. If it is higher than 0.2%, the thickening performance will be seriously affected. But the control of water content is not easy to be stable. The water content of each batch of products often changes. Even in the same batch of products, the water content of each barrel of resin may fluctuate. If there is water pollution or condensation of water vapor in the barrel before loading, the water content in the resin will change, which will affect the thickening process. Special attention should be paid to this.

(7) molecular weight requirements. The number average molecular weight m n of polyester is very sensitive to the effect of thickening property. Weight average molecular weight M W and Z average molecular weight m Z have more accurate correlation with the thickening process. The number average molecular weight can be calculated by measuring acid value and hydroxyl number. The dispersion of resin molecular weight can be analyzed by the measurement of the above molecular weight statistical average. However, this kind of measurement and calculation is time-consuming and requires more complex instruments.

2.Fillers:

Filler is a solid additive used to improve the properties of composite materials (such as hardness, rigidity, impact strength, etc.) and reduce the cost. It is different from reinforcement materials, and the filler is granular. The function mechanism of fillers is: Fillers act as additives, mainly by occupying the volume. Because of the existence of fillers, the molecular chains of matrix materials can no longer occupy all the original space, so that the connected segments are fixed to some extent, and may cause the orientation of matrix polymers. Due to the size stability of fillers, the movement of molecular chains in the polymer interface area is limited, which makes the glass transition temperature rise, the temperature of thermal deformation rise, the shrinkage rate decrease, and the modulus of elasticity, hardness, rigidity and impact strength increase.

Filler is an important part of molding plastics, its amount is very large, generally can play the following role.

Filler is an important part of molding plastics, its amount is very large, generally can play the following role.

① reduce the shrinkage of the formed parts, improve the dimensional stability, surface finish, smoothness and flatness or matte of the products.

② effective viscosity regulator of resin.

③ it can meet different performance requirements, improve wear resistance, improve conductivity and thermal conductivity, etc. Most fillers can improve the impact strength and compression strength of the material, but not the tensile strength.

④ it can improve the coloring effect of pigment.

⑤ some fillers have excellent light stability and chemical corrosion resistance.

⑥ it can increase capacity, reduce costs and improve the competitiveness of products in the market.

The main factors that should be considered in the selection of fillers are price, density, adsorption resin quantity, filling quantity and particle size distribution, and the influence of fillers on liquid and curing properties should also be considered. Generally speaking, there are some requirements for the selection of fillers as follows.

① the filler should be dry and easy to disperse in the resin. The amount of resin adsorbed is low and it has good wettability to the resin.

② there is no adverse effect on resin curing reaction and product performance after curing.

③ for products with large thickness, good thermal conductivity is also required.

④ low cost.

The types of fillers are silica and silicate, carbonate, sulfate and oxide. These fillers are all natural minerals. Before use, they should be ground or processed by chemical precipitation method. During use, attention should be paid to their density to avoid precipitation and separation of fillers in resin. Several typical fillers are introduced below.

(1) calcium carbonate is one of the most basic fillers, which has rich sources, low price, the lowest oil absorption value, the highest dosage in the formula, and good covering characteristics. However, CaCO 3 filler has a tendency of preferential flow during the molding process. According to the research, in order to obtain the best performance, the filler should be controlled in a rather narrow range. In SMC formula, the ratio of filler dosage to resin dosage is generally (1.0-2.0): 1 (mass ratio).

(2) kaolin kaolin, commonly known as porcelain clay, is a hydrated aluminum silicate mineral and an ideal filler. Good fluidity is its main characteristic. When forming, it has the weakest preferential flow tendency. It not only has enough resistance to make the reinforcing materials cross each other, but also can fill the narrow dead angle and other parts of the cavity. Compared with calcium carbonate filler, it can provide more compact products, lower water absorption, higher impact strength and lower ability of fiber segregation.

There are two main types of kaolin products: natural hydrated kaolin and calcined anhydrous kaolin. The hydrated kaolin has no abrasiveness, high chemical stability and high specific surface area, so it has high viscosity. The calcined kaolin is much harder, and its Mohs hardness is 2-4 times of the former, but its application in thermosetting plastics can give the products excellent electrical properties. In addition, kaolin can be treated with various surface treatments, so that the system with kaolin can obtain excellent water resistance, electrical performance and reinforcement.

When kaolin is used as filler in FRP system, more resin is needed to be soaked, and it tends to absorb or lose water with the change of environment. Therefore, it is more difficult to control thickening in SMC / BMC system, thus limiting the application of filler. Kaolin makes FRP products yellow or brown, which is not conducive to FRP color matching, especially with light color.

(3) talc is a hydrated magnesium silicate, which is usually mined underground. Talc is one of the most minerals that can be floated. Most talc is milled to an average diameter of 6 μ m, but soft talc can produce 70% talc with particle size less than 2 μ M.

Talc has the same properties as kaolin, good fluidity, and gives the molding material better color. At the same time, it can increase the water resistance of the molding products, improve the electrical strength, and improve the post molding processing. However, its oil absorption value is high and its addition amount is low.

In the SMC / BMC formulation, the function of talc filler is mainly to remove the viscosity and excessive flow of textile materials in the forming process. But it is not generally used as a main filler. A small amount of talc filler combined with water milled calcium carbonate can be used as a substitute of precipitated calcium carbonate after surface treatment in FRP formula. Talc can be used as a flow control agent, and can also be used to reduce the water absorption of molded parts.

(4) silica is the most abundant material in the earth’s crust. It occurs in crystalline form such as quartz, and the less pure forms are sand and flint. Silica sand which has been washed, dried and graded can be used as filler of polyester resin and epoxy resin system.

The milled and purified silica or quartz powder can also be used as wear-resistant filler, which has low thermal expansion and good electrical insulation, and is widely used in the epoxy resin system in the field of electrical application.

Silicon dioxide is a kind of high abrasive filler, which will cause damage to the surface of the mold during the processing. In addition, it is very difficult to machine parts with silica as filler, so tungsten carbide or diamond tools are needed.

(5) hydrated alumina hydrated alumina is a kind of flame-retardant filler, which can release binding water under the flame without the toxicity of general chemical fire extinguishing agent. The particle size of alumina trihydrate is different, and its oil absorption is similar to that of calcium carbonate. Its filling density is lower than that of calcium carbonate. Trihydrate alumina is a good substitute for ordinary fillers in flame retardancy. Above 200 ℃, it can be decomposed into alumina, which can absorb heat to produce flame retardancy. Water vapor can replace oxygen and cover the flame. Its flame retardancy can be carried out without halide.

Another important advantage of alumina trihydrate is that it can reduce the smoke emission rate and improve the arc resistance. The disadvantage is that the filling density is decreased, so the resin fluidity is obviously decreased, so the dosage cannot be too much.

3.Initiator:

Initiator is a kind of substance which can activate the low molecule with double bond in monomer or linear molecular chain to become free radical and chain reaction. Initiator can be classified according to chemical composition and structure, molding temperature and physical state of initiator itself.

The initiators classified by chemical composition and structure are as follows.

The initiators classified by chemical composition and structure are as follows.

(1) organic peroxides can be regarded as the derivatives of hydrogen peroxide with different organic substituents. The following types of organic peroxides are used in unsaturated polyester: alkyl (or aryl) hydrogen peroxide; dialkyl peroxide (or aryl peroxide); diacylperoxide; peracid ester; dicarbonate peroxide; ketone peroxide.

(2) azo initiators are not easy to decompose under temperature. When the temperature is constant, the decomposition rate of dilute form is the same as that of pure liquid form, and the decomposition rate is not affected by the environment. Therefore, azo compounds are very suitable for curing resins containing various additives. They bring excellent durability to unsaturated polyester resins and are also safer than peroxides with similar activity.

(3) with the appearance of BMC, SMC molding compound and pultrusion process, the composite initiator compound initiator requires that the unsaturated polyester resin initiator system has a longer application period, and can be quickly gel and solidified, or can be quickly gel and has a longer curing time. The mixture of high temperature initiator and active low temperature initiator can form two or more than two kinds of initiators. It is very important to form a composite initiator system.

According to the specific molding process, the initiator is selected according to the following two aspects: the storage period of resin / peroxide mixture and the curing speed of molded products. See table 4-13 for the common types and characteristics of typical SMC initiators.

4.Inhibitor:

Polymerization inhibitor refers to the substance that can rapidly react with free radicals, slow down or inhibit unwanted chemical reactions, and is used to extend the storage life of some monomers and resins, also known as polymerization terminator, which includes polymerization inhibitor and polymerization retarder. The polymerization inhibitor can prevent the polymerization. In the polymerization process, there is an induction period (a period of time when the polymerization rate is zero). The length of the induction period is directly proportional to the content of polymerization inhibitor. After the consumption of polymerization inhibitor, the induction period ends, i.e. it is carried out at the normal rate when there is no polymerization inhibitor. Unsaturated polyester resin is a mixture of resin and cross-linked monomer, in which there is often no initiator and self polymerization will occur, so the polymerization inhibitor can be added. The common polymerization inhibitors of SMC are p-benzoquinone and hydroquinone.

Polymerization inhibitor refers to the substance that can rapidly react with free radicals, slow down or inhibit unwanted chemical reactions, and is used to extend the storage life of some monomers and resins, also known as polymerization terminator, which includes polymerization inhibitor and polymerization retarder. The polymerization inhibitor can prevent the polymerization. In the polymerization process, there is an induction period (a period of time when the polymerization rate is zero). The length of the induction period is directly proportional to the content of polymerization inhibitor. After the consumption of polymerization inhibitor, the induction period ends, i.e. it is carried out at the normal rate when there is no polymerization inhibitor. Unsaturated polyester resin is a mixture of resin and cross-linked monomer, in which there is often no initiator and self polymerization will occur, so the polymerization inhibitor can be added. The common polymerization inhibitors of SMC are p-benzoquinone and hydroquinone.

5.Release Agent:

In SMC process, there are two types of mold release agents: one is external mold release agent, which is pre coated on the hot metal mold surface before SMC molding; the other is internal mold release agent, which is added into the resin paste formula in the process of manufacturing SMC mold plastics. Because unsaturated polyester resin is polar, it has a certain affinity for the surface of metal mold. Most of the internal release agents are long chain fatty acids and their salts, which will melt when heated and migrate to the surface of the mold as a second phase, so it can prevent the adhesion of polyester resin to the surface of the mold. In this sense, the melting point of the selected internal release agent should be slightly lower than the curing temperature, so as to minimize the possibility of adhesion to the surface due to premature melting of the release agent before curing. As an internal release agent, it must also meet the following requirements:

① it must be compatible during the processing;

① it must be compatible during the processing;

② it should not have harmful effects on the physical properties of the final product;

③ it will not produce undesirable color or color drift;

④ it is convenient for the mixing operation of adding resin paste. In SMC, stearic acid metal salt is mainly used as internal release agent.

7.Thickener:

Thickener is a chemical thickening agent, which can increase the viscosity of resin to non-stick hand. The ideal thickening process of SMC requires that in the impregnation stage, the resin thickening should be slow to ensure good impregnation of glass fiber; after impregnation, the resin thickening should be fast enough to enable SMC to enter the molding stage as soon as possible and reduce the inventory as much as possible; when the viscosity of SMC reaches the molding viscosity, the thickening process should stop immediately and be stable to obtain the longest storage life as possible.

The basic principle of chemical thickening is as follows.

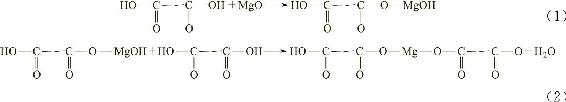

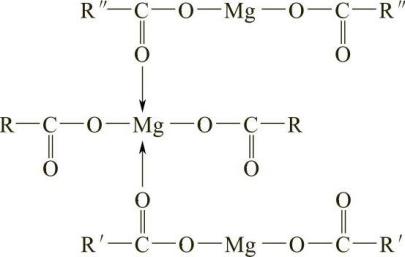

The thickening reaction of polyester resin is divided into two stages. The first stage is an acid-base salt formation reaction between the carboxyl end group of polyester resin and alkaline earth metal oxide. Taking MgO as an example, the reaction process is as follows:

As the linear chain grows, the molecular weight increases, and then the viscosity of the system increases due to the entanglement between larger molecules.

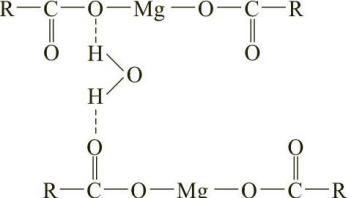

The second reaction is to form a bridge network and further increase the viscosity. The first reaction is the formation of hydrogen bond between hydroxyl and ether oxygen of adjacent polyester resin molecules. These oxygen are all power supply daughters. The acceptor in this reaction is the hydroxyl in water, alcohol and other hydroxyl containing molecules. This reaction can be described as follows:

Each polymer molecule has a lot of such oxygen, so it can form a large grid. Although each of these hydrogen bonds is very weak, the existence of a large number of hydrogen bonds will produce enough viscosity increase results.

The second reaction is to form a complex between the carbonyl group of polyester and the metal atom in the alkaline earth metal oxide or hydroxide:

The grids formed by these coordination complexes also produce the result of viscosity increase.

These multiple reactions do not occur independently of another, they occur simultaneously and are affected by the parameters of the machining process of other chemicals in the molding compound.

It has been pointed out that in order to increase the viscosity of polyester resin paste from low viscosity to moldable viscosity in a certain period of time, it is necessary to add a proper thickener. This thickening process can make the molding plastics with high content of glass fiber and keep the good clustering of glass fiber at the same time.

But in the specific application, in order to obtain the routine thickening, it is a very difficult task to select the appropriate thickener, and many factors must be weighed.

① the viscosity of the resin paste must be increased slowly so that the glass fiber can be well impregnated.

②The viscosity of resin paste must be increased rapidly enough to eliminate or at least minimize the separation of incompatible low shrinkage additives.

③ the viscosity of resin paste should increase rapidly to the viscosity enough for molding in a certain period of time, which will keep the storage capacity of molding plastics to a minimum.

④ the viscosity of resin paste must be high enough to drive the glass fiber to flow together in the molding process.

⑤ when the viscosity of resin paste reaches the molding range, it must be kept in a stable state.

The thickening curve of resin paste must be repeatable.

Obviously, there are many conflicting requirements for thickening speed. It must be fast for one feature and slow for another. Therefore, the whole process must be analyzed to determine the best thickening curve of each resin paste. In addition, induction time is also a very important factor, which controls the resin impregnation of fibers. If the thickening is too fast during this period, dry spots will appear in the sheet, and the short induction time will bring difficulties to the processing of SMC sheet on the unit. The thickener’s thickening speed, induction period and the smoothness after reaching the molding viscosity can be controlled by the thickener’s type, concentration and particle size.

8.Colorant:

Colorant is the general term of organic and inorganic, natural and synthetic colorants that can make products colored. There are two kinds of colorants: dye and pigment.

(1) dye dye is a strong colorant applied to the substrate to make it have color. The dye is retained in the base material by adsorption dissolution, mechanical bonding, ionic bond chemical bonding or covalent bond bonding, but the dye is easy to be partially dissolved in the plastic. It is characterized by good transparency, high colouring strength and low density, but they have poor heat resistance and color migration tendency. For these reasons, they are rarely used in polyester molding materials.

(2) pigment is a kind of organic or inorganic matter with large particle size and usually insoluble in common solvent. Organic pigments produce translucent or nearly transparent colors, which have better color shift resistance and slightly higher heat resistance than dyes. Except for a few inorganic pigments, all of them are opaque, with strong wear resistance, heat resistance and color shift resistance, good covering power and bright color.

In SMC process, the success or failure of coloring and its reproducibility are affected by the following factors: the strength of color, the choice of pigment, the degree of monomer loss, the degree of thickening, the appropriate mold temperature and forming pressure, the matching tightness of mold, etc.

It should be noted that the successful use of pigments in one SMC does not guarantee success in the other. Therefore, it is necessary to match a specific SMC with a specific colorant in order to obtain an ideal coloring effect.

In the preparation of color paste, the content of pigment is 15% – 75%, which depends on the variety of pigment and oil absorption value. The dosage of SMC is generally 0.1% – 7%, white is 0.25% – 12%. In most cases, adding a small amount of white pigment can improve the transparency, stability and consistency of the color. The selection of colorant mainly depends on the user’s requirements, the synergistic effect of each component of the formula and the whole process itself. The colorant must meet the following requirements.

① it has good thermal stability and will not decompose or fade during the forming process.

② it has good light stability and will not fade or be relatively stable under the action of light.

③ it is easy to disperse and does not migrate.

④ the color is bright and strong.

⑤ it has no obvious influence on the storage, thickening, molding, flow, curing and other characteristics of SMC, as well as the mechanical properties, weather resistance and electrical properties of the final product.

⑥ non toxic, non polluting to the environment, abundant sources and moderate price.

9.Low shrinkage additive:

In general, the polyester resin system has thermal shrinkage of 5% – 7%, while the filler and glass fiber reinforced material have very low thermal shrinkage. In the molding plastics, the unmatched shrinkage behavior of these components will produce high stress in the resin / filler phase between the reinforcement materials. Under the effect of the stress generated by the uneven shrinkage, the best result is that there are ripples on the surface, and the worse result is that there are warps and holes in the product, at the same time, the accuracy of the repeatability of the product surface will be reduced, and on the surface Leave fiber pattern, internal will produce cracks, and affect the product to obtain precise tolerance dimension.

In order to quantify this effect, the volume change of a typical unsaturated polyester resin in the curing process was measured by an expansion tester in the relevant research. The volume change curve is shown in Figure 4-14. The result shows that the final volume shrinkage is about 7.1%.

In order to reduce the shrinkage of polyester molding products, prevent resin cracking during processing, and improve the smoothness of the product surface, a low shrinkage additive was added to the formula of molding materials. Low shrinkage additives are generally rubber elastomer, thermoplastic polymer or modified polyurethane.

In order to reduce the shrinkage of polyester molding products, prevent resin cracking during processing, and improve the smoothness of the product surface, a low shrinkage additive was added to the formula of molding materials. Low shrinkage additives are generally rubber elastomer, thermoplastic polymer or modified polyurethane.

In unsaturated polyester resin, there are two types according to the compatibility of low shrinkage additives and polyester resin. One is incompatible low shrinkage additives, such as polyethylene, PVC, etc. Incompatible low shrinkage additives can improve the surface roughness of polyester molding plastics, because they reduce the content of shrinkable components, improve the rheological properties of polyester molding plastics, and make the glass fiber get more uniform distribution in molding products. At the same time, because of its incompatibility, a thermoplastic film will be formed on the surface of the product. Another kind of low shrinkage additive is a kind of compatible additive before the curing reaction. Its mechanism of low shrinkage is complex, but the real “zero” shrinkage or even “negative” shrinkage can be obtained by using this kind of additive. In SMC / BMC system, the most commonly used low shrinkage additives are styrene powder, polystyrene and its copolymer, PVC and its copolymer, cellulose acetate, cellulose butyrate, thermoplastic polyester, polyvinyl acetate and polymethyl methacrylate.

Among the common low shrinkage additives, PS and HDPE powder are used as the main additives of SMC low shrinkage system, and their shrinkage effect is usually 0.1% – 0.3%. They cannot be used in low profile systems because they cannot achieve precisely controlled dimensional tolerances. However, they have good color acceptability and can obtain good color depth in almost all pigment systems. PS is often used as additive in low shrinkage coloring system, but because PS is not chemically bonded in the system, it will be separated in SMC storage or molding. This problem can be avoided by improving the formulation, such as adding more fillers or mixing different fillers to improve the viscosity of resin paste.

PVAc and PMMA are often used to produce products with relatively low shrinkage. The shrinkage effect is 0-0.05%, and the addition amount is 10% – 20% of resin. These materials can be used as true low profile additives to provide products with “zero” shrinkage, as well as good molding fluidity and excellent surface. However, it is not suitable for colouring system because of its poor colouring acceptance.

It is believed that the most possible mechanism of these thermoplastic additives in anti shrinkage is as follows.

① when the temperature rises, organic materials will expand in SMC.

②The decomposition of peroxides caused the polymerization of unsaturated polyester resin and styrene.

③ the soluble additives become insoluble in the up styrene copolymerization system and precipitate to form the separated phase.

④the above separated phases become the accumulation sites of up and styrene.

⑤ with the increase of temperature, the larger expansion of the separation phase and the vapor pressure of styrene offset the polymerization shrinkage of up styrene.

⑥ the up styrene residue in the separation phase polymerizes and contracts to form pores.

⑦ when the product begins to cool down, the thermoplastic separation phase and resin phase begin to contract. When up reaches the glass transition temperature, the thermal shrinkage of up phase is much smaller than that of thermoplastic additives. The thermal shrinkage of the thermoplastic additive forms pores and spreads all over the separated phases.

Therefore, in this system, the thermal expansion of thermoplastic resin phase is the main factor to control the shrinkage. The glass transition temperature of low shrinkage additives and the expansion before and after glass transition also have a great influence on the effect of shrinkage control.

10.Other additives:

In the SMC / BMC molding process, because of its many components and different physical forms, it is a complex multi-phase system, so there are many factors involved in the whole manufacturing process. Therefore, in the actual operation process, there will be some problems that are difficult to solve, such as the uniformity and repeatability of molding plastics are difficult to control; each component is easy to have phase separation in the resin paste system, especially the low shrinkage additives and colorants; each production link is easy to mix with air to form bubbles; the viscosity of resin paste is too large, and the process performance changes. Poor etc. At present, the important way to solve these problems is to add special additives such as wetting dispersant, phase separation stabilizer, viscosity reducer and so on.

There are two types of molecular structures in the filler wetting dispersant: one is the single functional molecular structure, which adsorbs on the particle surface and reduces the interaction between molecules, so as to achieve the effect of reducing viscosity; the other is the dual functional molecular structure, which adsorbs on the particle surface and reduces the interaction between particles, and can produce some bridging effect. This structure can not only reduce the viscosity of the system, but also improve the color uniformity of the resin paste.

Origin of the Article:Forming Technology and Application of Composite Materials Editor:Professor:Jiakang Huang

Condition Description Reasons Solution 1 a semicircular swell on the surface of solidified fi……

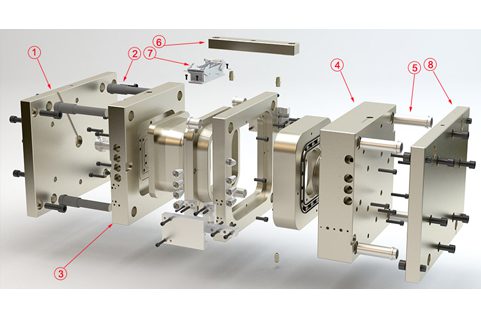

Item Description Function 1 Top clamp plate To connect the compression mold with the hydraul……

Overview: Since the fiberglass compression molding process has some outstanding advantages, it pla……