| Condition | Description | Reasons | Solution |

| 1 | if there are too many small holes in the surface it will be difficult to release the fiberglass molding products. | The feeding area is too large, and the surface air is not discharged due to the short process | Reduce the feeding area and add small material sheet at the top of the large sheet. |

| 2 | The clipping edges are too large. | Repair clipping edges. | |

| 3 | There is dry fiber.The initial viscosity of the resin paste is too high. The glass fiber is not fully saturated. | Reduce the initial viscosity of the resin paste, increase the work roll in the impregnation area, and replace the glass fiber. | |

| 4 | Pre-gelled area on the fiberglass molding part | Reduce mold temperature and add inhibitor to resin paste. | |

| 5 | SMC material dry | When using the anti-seepage film to wrap the SMC material, the quantity of zinc stearate can not be prepared too much. | |

| 6 | Fiberglass SMC material too soft. | Increase thickening time or increase thickening temperature to increase thickening viscosity level. | |

| 7 | Insufficient pressure | Increase molding pressure |

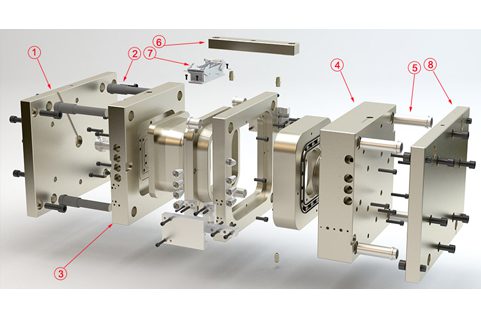

Item Description Function 1 Top clamp plate To connect the compression mold with the hydraul……

3D Printing Technology is not unfamiliar to us. It is one of the most advanced manufacturing metho……

The basic process of short fibre moulding is to put a certain amount of pre-treated moulding mater……